CNC Machining Services: Remodeling Fashionable Manufacturing with Precision and Automation

CNC Machining Services: Remodeling Fashionable Manufacturing with Precision and Automation

Blog Article

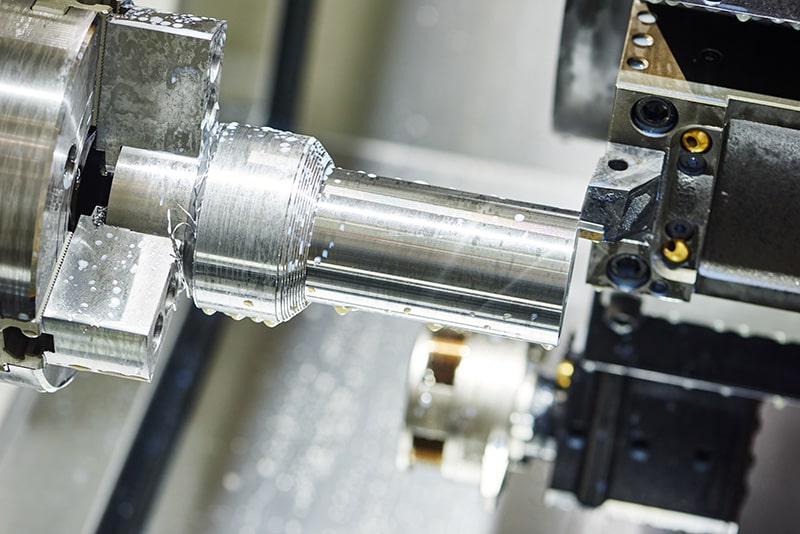

CNC machine, which stands for Computer Numerical Control machining, has revolutionized the world of manufacturing, bringing accuracy, efficiency, and automation into the process of production. This technology uses computer-controlled machines to cut, shape and manufacture complex components and parts made of materials like metal or plastic, wood as well as composites. Through automation of many operations that were previously dependent on humans to perform, CNC machining has significantly enhanced the speed and accuracy of production, which makes it indispensable in industries like automotive, aerospace, medical, and electronics. Incorporating computers into machining tools has opened up many new opportunities in the manufacturing of complex and accurate components, enhancing both the efficiency and quality of manufacturing.

One of the most significant benefits of CNC machine is the ability to make highly detailed and complex parts that would be almost impossible to construct using conventional manufacturing processes. CNC machines operate based on digital designs, meaning that when a design is programmed into the machine, it can be replicated precisely and with consistency. This is especially useful in areas like aerospace, automotive, as well as electronics, where precision is essential. In addition, CNC machining is capable of working with a wide variety of materials, starting from soft plastics, to metals. This lets manufacturers make parts that are able to meet certain needs for toughness, durability, and heat resistance. The versatility of CNC machining has opened up the possibility of new product designs as well as engineering.

One of the main advantages of CNC machine is the flexibility to work with a vast variety of different materials. Whether manufacturers are dealing with hard metals like steel and titanium or softer materials like plastic and wood CNC machines are equipped to tackle a range of cutting and shaping tasks. This is what makes CNC machine-making suitable for the production of components in a range of fields, from medical devices and aerospace components, to automotive and consumer electronics. Being able to process complicated geometries while maintaining tight tolerances has also made CNC machining the go-to method for creating intricate parts that would be difficult to, if not impossible to create using conventional techniques.

One of the main features of CNC machining was using computer-aided designs or computer-aided manufacturing programs. CAD software lets engineers design precise 3D drawings of the items to be produced, while CAM software translates these designs into machine directions. This seamless connection between design and manufacturing ensures that the finished product is in line with the initial design specifications. Furthermore, CAD/CAM software facilitates rapid prototyping that allows manufacturers to test quickly and fine-tune their designs before committing to massive production. Ability to change the designs and make prototypes offers businesses an advantage in fields where innovation and speed to market are essential. To get additional information please look at https://www.premiumparts.com/services/cnc-machining

As well as efficiency and speed, CNC machining is valued for its cost-effectiveness, especially when producing large production runs. Once initial setup and the programming of the machine have been completed manufacturing additional components requires minimal input, reducing the overall cost of production. When manufacturing companies are working with high-end material like aerospace-grade alloys CNC manufacturing reduces waste through making the cutting process more efficient, ensuring that each part is made with the least amount of losses in material. This precision and efficiency make CNC machine a great choice for both prototyping and full-scale production, as it allows makers to swiftly test and refine designs, and keep production costs in check.

The environmental impact on the environment CNC machine is a different aspect worth taking into consideration. While traditional manufacturing methods often create a considerable amount of waste, CNC machines are well-known for their material efficiency. With precise cutting and shaping raw materials, CNC machining minimizes waste by minimizing both costs for materials and environmental impact. Additionally, the automation of CNC machines can reduce the energy usage as compared to manual machining. The majority of the modern CNC machines are also designed using sustainability in mind. making use of energy-efficient systems and motors for further reducing the carbon footprint of their machines. This makes CNC processing an eco-friendly alternative for businesses looking to reduce waste and conserve resources.